CORNET-successful project CCS on Ships: Carbon Capture as a Practical Solution for Maritime Emissions

CORNET-successful project CCS on Ships: Carbon Capture as a Practical Solution for Maritime Emissions

„CCS on Ships shows that CO₂ capture on board is technically feasible and can enable significant emission reductions under realistic boundary conditions. Especially as a bridging technology, CCS offers high potential to effectively decarbonize existing fleets long before climate-neutral fuels become available on a large scale.”

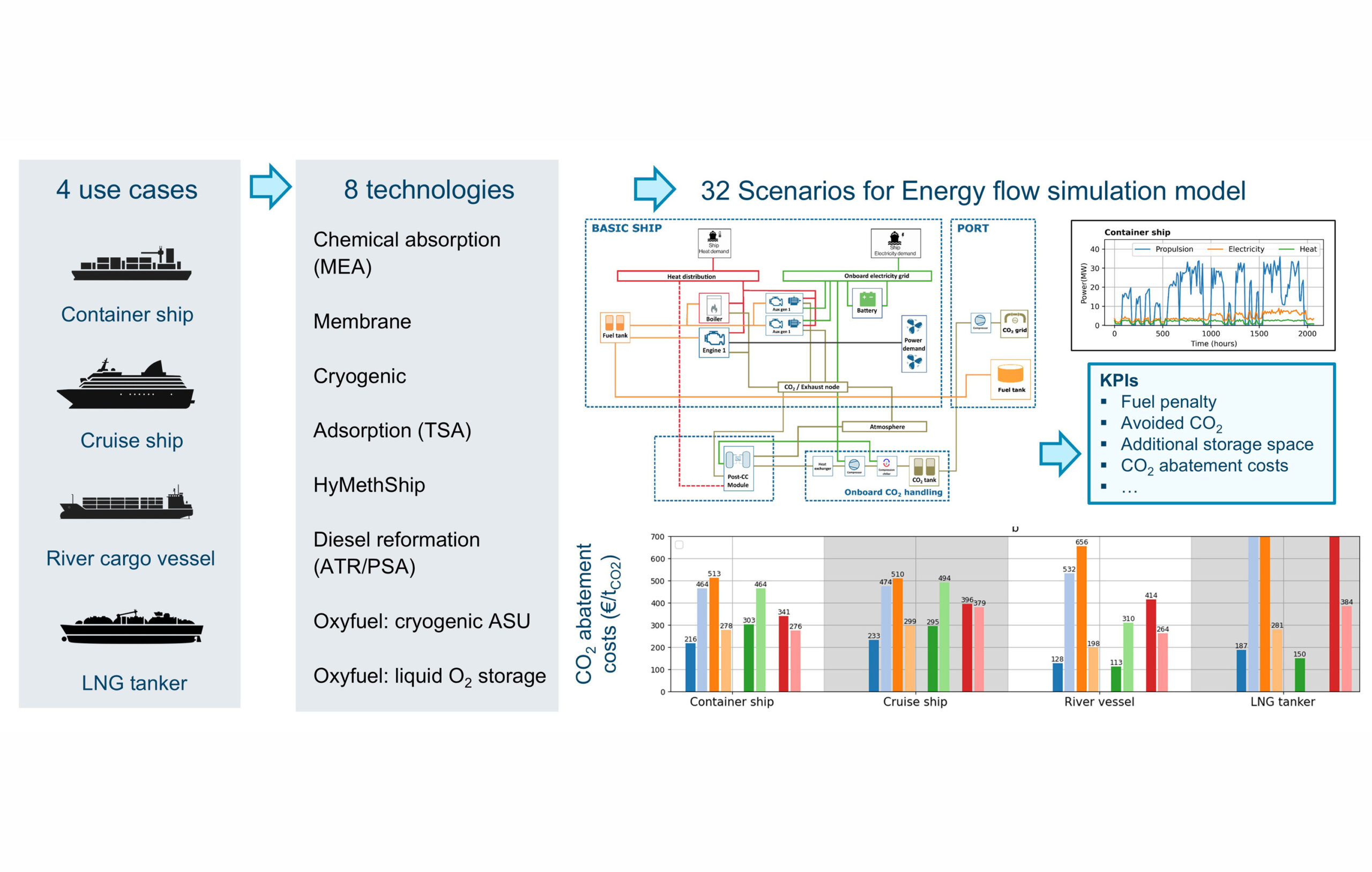

Techno economic evaluation with system Simulation with LEC ENERsim

Against this backdrop, the CORNET project “CCS on Ships” investigated the capture and storage of CO₂ directly on board ships (Carbon Capture and Storage, CCS) as a short-term, feasible bridging technology. LEC participated in the international research project together with Ruhr University Bochum and TU Bergakademie Freiberg.

CORNET is a European funding instrument for pre-competitive, industry-oriented research and enables, in particular, small and medium-sized enterprises (SMEs) to address practice-relevant issues in collaboration with research institutions. The project “CCS on Ships” is a successful example of how CORNET projects provide robust decision-making bases for industry and technology development.

Focus: Technical Feasibility under Realistic Conditions

The aim of the project was to systematically evaluate different CO₂ capture technologies and to analyze their integration into real ship systems. Using detailed simulation models, the project examined how various CCS concepts affect energy demand, operation, and overall system efficiency, as well as how storage and transfer of the captured CO₂ in ports can be technically implemented.

The LEC contributed its many years of expertise in the analysis of combustion engines, thermal system integration, and model-based evaluation of complex energy systems.

Key Results

The studies show, among other findings, that amine-based post-combustion processes—such as those using MDEA/PZ currently offer the best balance between technical feasibility and efficiency. For inland vessels, the additional fuel demand under certain conditions was only around seven percent, placing it within an acceptable range for practical application. Other investigated methods, such as membrane or cryogenic separation processes, proved to be currently unsuitable due to very high energy requirements and, in some cases, insufficient technology readiness levels.

A key success factor of amine-based processes is the use of waste heat available from the engine. In particular, concepts with higher exhaust gas temperatures, as found in four-stroke engines, enable significantly more efficient operation of CCS systems. In a container ship scenario, targeted thermal integration reduced the CO₂ avoidance cost from around €300 to €150 per tonne while simultaneously increasing the capture rate. The safe storage and handling of CO₂ on board were also assessed as technically manageable.

Relevance for Industry and Research

The project provides a solid technical foundation for future development decisions in the maritime sector—from engine and system manufacturers to ship and port operators. Validated models and realistic system concepts reduce development risks and open up new application and market potentials along the entire CCS value chain.

Industrial partners such as Robert Bosch GmbH, which chaired the project advisory board, used the results directly for internal technology and strategy analyses—also beyond the maritime application case.

Outlook

The project benefited from close cooperation between German and Austrian partners with complementary expertise in engine technology, thermodynamics and process engineering. In parallel, the IMO has officially recognized CCS as a possible decarbonization pathway for shipping, and classification societies are working on corresponding regulatory frameworks for onboard systems.

We would like to thank the CORNET consortium for this excellent collaboration!

The Institute of Thermal and Fluid Dynamics (ITF) at Ruhr-Universität Bochum under the direction of Prof. Dr.-Ing. Roland Span, the Institute for Energy Process Engineering and Chemical Engineering (IEC) at the Technische Universität Bergakademie Freiberg under the direction of Prof. Dr.-Ing. Martin Gräbner, the Large Engines Competence Center (LEC) under the direction of Dipl.-Ing. Dr. Thomas Jauk and Dr.-Ing. Nicole Wermuth, and the Institute of Thermodynamics and Sustainable Propulsion Systems (ITnA) at Graz University of Technology under the direction of Univ.-Prof. Dipl.-Ing. Dr.techn. Helmut Eichlseder.

Scientific research assistants –Vanessa Kaub, M.Sc. (ITF), Antonia Helf, M.Sc. (IEC), Dr.-Ing Florian Keller (IEC), Dipl.-Ing. Dr. techn. Michael Wohlthan (LEC), Dipl.-Ing. Dr. techn. Bernhard Thaler (LEC), Dipl.-Ing. Dr. techn. Gerhard Pirker (LEC) and Dipl.-Ing. Thomas Oppl

(ITnA) – for the implementation of the project. Special thanks are due to the FFG (Austrian Research Promotion Agency) for funding the project within the framework of the collective research networking (CORNET) programme as well as the FVV eV for additional funding. The project was conducted by a working group led by Dr.-Ing. Klaus Meyer (Robert Bosch GmbH).

We gratefully acknowledge the support received from the project coordination and from all members of the project user committee.