The highly flexible software package can be used to analyze and simulate a wide range of processes in the combustion engine. LEC CORA can be flexibly adapted to customer requirements and can be integrated into simulation programs from other suppliers. LEC CORA was developed to close a gap: Although there are many software solutions for engine analysis, they are often limited in their flexibility and especially in their use for highly specialized applications. LEC CORA addresses precisely this issue and focuses specifically on combustion engines – the area in which the LEC team has built up expertise and an international reputation over decades.

Applicable for different fuels

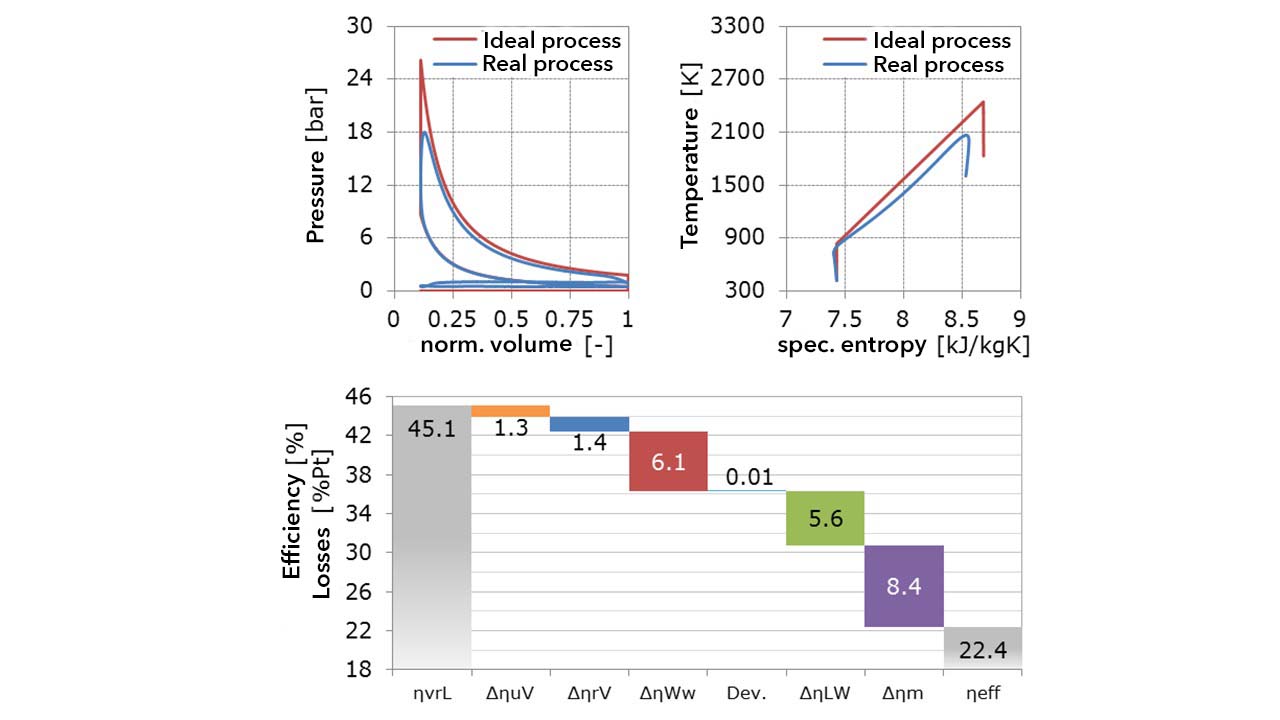

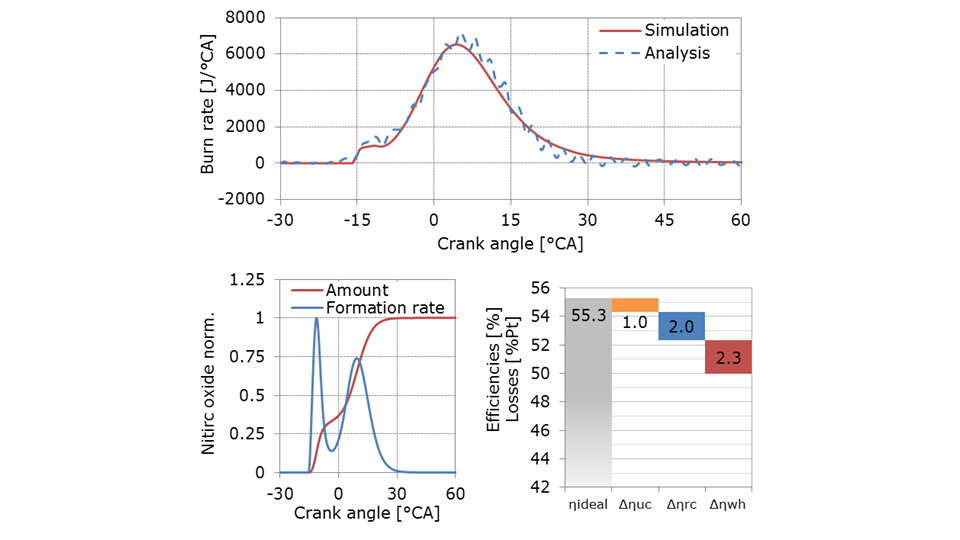

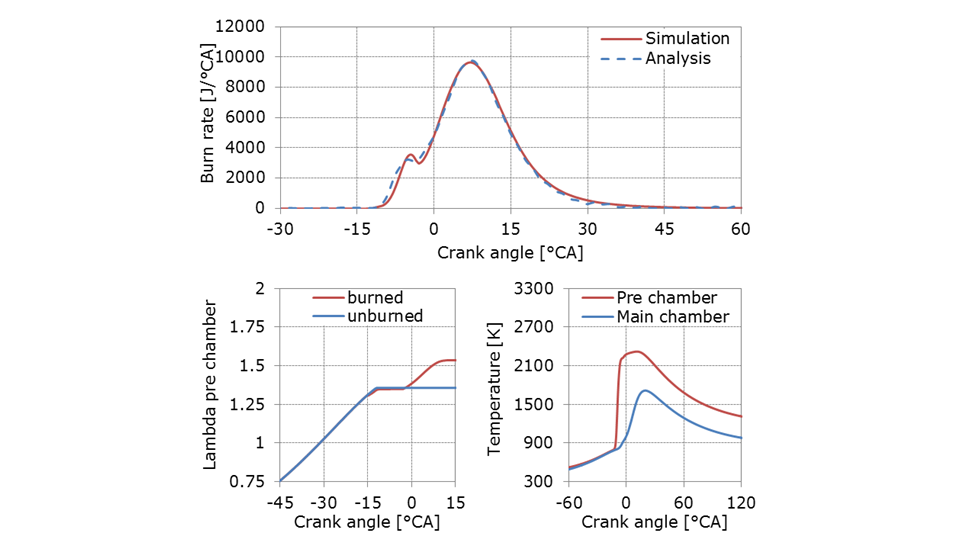

The LEC CORA software package enables the zero-dimensional analysis and simulation of different working processes in the combustion engine, with automated evaluation. The focus is on the high-pressure part of the working process based on one- and two-zone models, taking into account various wall heat transfer models. It is possible to work with different wall heat transfer models as well as fuels (gasoline, diesel, natural gas, H2,…) and fuel combinations (dual-fuel). LEC CORA is also the ideal solution for knock detection and knock simulation as well as the simulation of nitrogen oxide emissions.

Simulation and analysis

Due to its modular structure, LEC CORA is also compatible with other software solutions (e.g. 1D charge exchange calculation), which enables even greater flexibility. Both simulation and analysis can be implemented with the innovative software. For example, an optimal combustion process can be simulated for a variety of modern combustion processes (open chamber, prechamber, DI …) and measurement data can be obtained from this. An analysis based on an actual measurement is also possible.