Unique research infrastructure for green energy and transportation solutions

Climate change is advancing, global energy demand and transport volumes are increasing. Together with partners from science and industry, the LEC Campus Inffeld at Graz University of Technology is working at full speed to make energy and transport systems more sustainable, efficient, robust and flexible in order to achieve the climate targets.

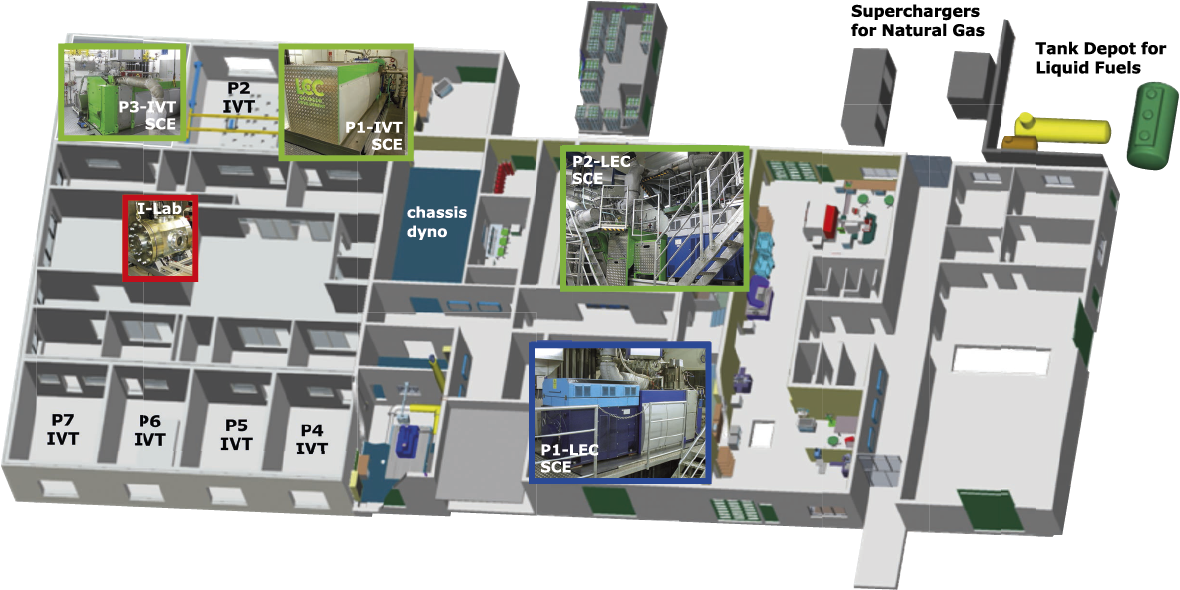

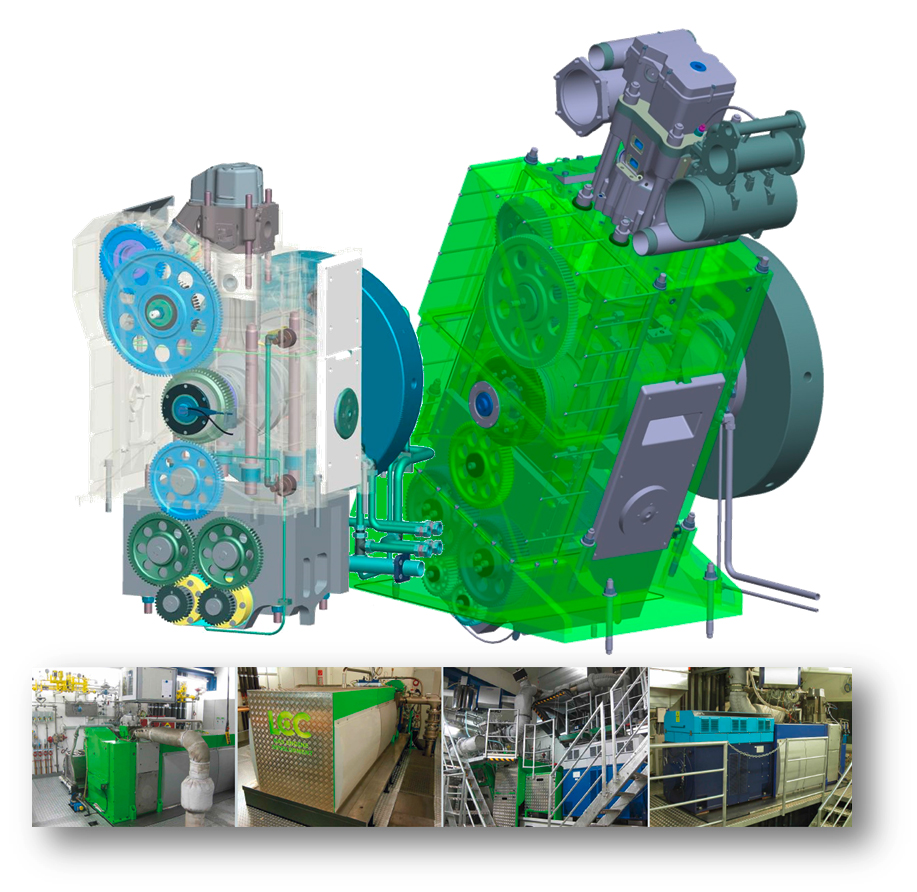

In addition to excellent know-how and experience, this requires a high-performance, highly flexible infrastructure with which different requirements and issues from industry can be addressed individually and quickly. The LEC has made a name for itself worldwide in this regard. The infrastructure is considered unique by experts from all over the world. The virtual design methodology has received several awards. This basis enables the LEC to try out and test new trends and ideas earlier than others. Such as drive solutions with hydrogen or other e-fuels.

The high flexibility with regard to different infrastructure requirements, coupled with comprehensive simulation know-how, make the LEC a pioneer and first point of contact for industry when it comes to sustainable solutions for the future.